Pipe relining is a modern, trenchless technology used for repairing and renewing damaged underground pipes or deteriorated pipes, including the ability to repair underground PVC pipes without digging. This method involves inserting a new pipe lining into existing pipelines, effectively creating a “pipe within a pipe” to restore functionality and extend the life of the sewer, water, or gas lines. Unlike traditional pipe repair methods that often require extensive excavation to remove and replace the old pipes, pipe relining is less invasive, more cost-effective, and can be completed in a shorter timeframe.

The process of pipe surface, begins with a thorough inspection of the existing pipe system to assess the extent of the damage and determine the most appropriate relining solution. This initial step is crucial for ensuring the success of the relining project, as it allows for a customized approach tailored to the specific conditions and requirements of the pipeline system. By preserving the existing landscape and infrastructure, pipe relining offers a sustainable and efficient alternative to conventional repair techniques, making it an increasingly popular choice for municipal and residential applications alike.

The Importance of Inspection in Pipe Relining

Before any relining project can commence, a detailed inspection of the existing pipe system is essential. This preliminary step serves several critical functions post relining inspections: it helps identify the type, location, and extent of the damage; determines the feasibility of choosing pipe relining alone as a repair method; and informs the selection of materials and techniques to be used. Without a comprehensive inspection, it would be impossible to devise an effective relining strategy that addresses all underlying issues.

Inspections are typically conducted using closed-circuit television (CCTV) cameras that provide clear, real-time visuals of the pipe’s interior. This allows technicians to accurately assess the condition of the pipeline, including any cracks, blockages, or other defects. The data collected during the inspection phase is then analyzed to create a detailed report, highlighting the areas in need of repair or inspection services and recommending the best course of action.

The importance of this inspection cannot be overstated. It not only ensures that the relining process is tailored to the specific needs of the pipeline but also helps avoid unnecessary expenses by accurately targeting the repair efforts. Furthermore, a thorough inspection minimizes the risk of unforeseen complications during the relining process, leading to more predictable outcomes and improved long-term performance of the newly relined pipes. By laying the groundwork for a successful and the role of inspection and diagnosis in effective pipe relining project, the initial inspection plays a pivotal role in the overall effectiveness and efficiency of pipe rehabilitation efforts.

Types of Pipe Inspection Techniques

To ensure the effectiveness of a pipe relining inspection project, a comprehensive inspection is crucial. This process utilizes various techniques, each with its unique advantages and applications. The most common methods include:

Visual Inspections

These drain inspections are the simplest form of inspections, involving manual checks by professionals. Visual inspections can be effective for assessing external damage or for preliminary evaluations. However, their scope is limited to what can be seen from the outside, making them insufficient for diagnosing internal pipe conditions.

Closed-Circuit Television (CCTV) Inspections

CCTV inspections are the cornerstone of modern pipe diagnostics. A waterproof camera, often mounted on a robotic crawler, is inserted into the pipe, providing high-resolution video footage of the pipe’s interior. This method plumbing inspection allows for a detailed assessment of the pipe’s condition, including the identification of cracks, blockages, corrosion, and other issues that could affect the full structural integrity of the pipeline.

Sonar Inspections

For pipes filled with water or other fluids that obstruct camera visuals, sonar inspections offer a viable alternative. By emitting sound waves and analyzing their reflections, sonar technology can map the interior of a pipe, revealing abnormalities like sediment build-up, collapses, and other structural defects.

Laser Profiling

Laser profiling involves the use of laser technology to measure and record the internal dimensions and shape of a pipe. This method is particularly useful for detecting deformations, such as sags or bulges, and for ensuring that the pipe length and diameter is suitable for relining.

Smoke and Dye Testing

Smoke and dye testing are used to identify leaks and points of ingress or egress in sewer lines. By introducing non-toxic smoke or dye into the pipeline, technicians can visually trace the source of leaks in sewer pipes, which is crucial for effective relining drain repairs.

The Role of Diagnosis in Identifying Pipe Issues

Following the inspection phase, the next critical step in the pipe relining process is diagnosis. This involves analyzing the collected data to understand the root cause, extent, and specific characteristics of the pipe damage. Accurate diagnosis is crucial for several reasons:

- Determining the Relining Method: The choice of relining method, whether Cured-in-Place Pipe (CIPP), slip lining, or another technique, depends on the nature and severity of the pipe damage. Accurate diagnosis ensures that the selected method will effectively address the identified issues.

- Material Selection: The type of material used for relining (e.g., resin types for CIPP) is also determined based on the diagnosis. Different conditions require different materials’ properties to ensure durability and functionality.

- Customizing the Solution: Each pipe relining project is unique, and a one-size-fits-all approach is seldom effective. Diagnosis allows for the customization of the relining process, ensuring that it is perfectly tailored to the specific needs of the pipeline.

- Cost Efficiency: By accurately identifying and targeting only the areas that need repair, diagnosis helps in optimizing the use of resources, thereby making the relining process more cost-effective.

- Preventing Future Issues: A thorough diagnosis can also help predict potential future problems, allowing for preventative measures to be incorporated into the relining process.

Advanced Diagnostic Tools and Technologies

The evolution of diagnostic tools and technologies has significantly enhanced the accuracy and efficiency of pipe inspections, paving the way for more effective, pipe replacement and relining projects. These advancements allow for a deeper understanding of pipe conditions, facilitating targeted interventions that address the root causes of pipeline issues. Among the leading-edge tools and technologies employed today are:

Robotic Crawlers

Equipped with high-definition cameras and various sensors, robotic crawlers can navigate through pipes, offering a close-up view of the pipe’s interior condition. These devices can traverse difficult terrain within pipes and provide real-time feedback, making them indispensable for thorough inspections of plumbing and sewer systems.

3D Scanning and Imaging

3D scanning technologies capture detailed images of the pipe’s interior, creating precise models that reveal deformations, cracks, and other structural anomalies. This comprehensive view of damaged pipe assists in planning the relining process with a high degree of accuracy.

Ground Penetrating Radar (GPR)

GPR is a non-invasive method used to examine the condition pipe integrity of pipes buried underground. By emitting radar waves into the ground, it can identify anomalies in pipe material, detect uncharted utilities in pipe walls, and assess the surrounding soil conditions that may affect the pipe’s integrity.

Infrared Thermography

This technique detects thermal irregularities in pipes caused by leaks, blockages, or structural weaknesses. Infrared thermography is particularly useful for identifying hidden plumbing problems or blocked pipes that other methods might miss.

Acoustic Emission Testing

Acoustic emission testing listens for the sounds made by cracks growing or leaks forming in old pipe. This method can pinpoint areas of concern within the pipe system, even in its early stages of failure, allowing for preventative pipe maintenance.

Preparing for Pipe Relining: From Inspection to Action

The transition from inspection and diagnosis to the actual relining process is a critical phase post relining, that requires meticulous preparation. This stage involves several key steps that ensure the final inspection of the relining project is executed smoothly and effectively:

Data Analysis and Reporting

The data gathered during the inspection and diagnosis phases are analyzed in detail to identify the specific issues and their locations within the pipe system. This analysis forms the basis of a comprehensive report that outlines the findings and recommends the most suitable relining methods.

Solution Design

Based on the diagnosis of pipe problems, a custom relining solution is designed. This includes selecting the appropriate relining technique, materials, and any special considerations required by the condition of the pipes. The design phase aims to create a tailored approach that addresses the identified problems while considering the operational requirements of the pipeline.

Material Selection

The choice of materials for the relining project is critical. Factors such as the pipe’s function, the nature of the transported material, environmental conditions, and expected lifespan influence the selection of relining materials. High-quality resins and liners are chosen to ensure durability and reliability.

Planning and Logistics

Effective planning and logistics are essential for minimizing the impact of the relining project on daily operations. This includes scheduling the work during off-peak hours if necessary, arranging for traffic management in public areas, and ensuring all necessary equipment and materials are on-site and ready for use.

Communication with Stakeholders

Before the project begins, it’s important to communicate the plan to all stakeholders, including municipal authorities, property owners, and the general public if applicable. Transparency regarding the project’s scope, timeline, and expected outcomes helps manage expectations and reduce inconvenience.

Material Selection and Custom Solutions Based on Diagnosis

The success of a pipe relining project largely depends on the correct selection of materials and the customization of solutions to meet the specific needs identified during the inspection and diagnosis phases. This tailored approach ensures that the relined pipe will perform optimally for its intended lifespan, resisting environmental stressors and operational demands.

Material Selection Criteria

The choice of materials for pipe relining involves considering various factors, including:

- Pipe Material and Condition: The existing pipe’s material (e.g., clay, concrete, PVC) and its condition influence the selection of relining materials to ensure compatibility and adhesion.

- Operational Environment: The chemical composition of the transported medium, temperature, pressure, and external environmental conditions (e.g., soil type, groundwater level) dictate the resilience required of the relining materials.

- Durability and Lifespan: Materials must be selected based on the expected lifespan, with considerations for wear and tear, corrosion resistance, and maintenance requirements.

- Installation Ease and Efficiency: The chosen materials should facilitate a smooth installation process, minimizing downtime and disruption.

Custom Solutions

Following the diagnosis, custom solutions are crafted to address the specific challenges identified. This might involve:

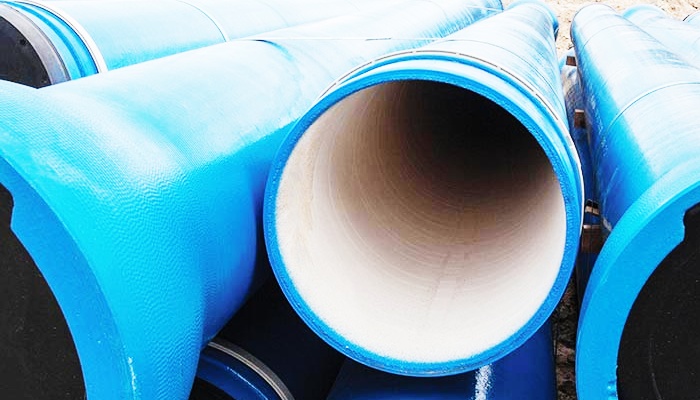

- Cured-in-Place Pipe (CIPP) Linings: For pipes with minor to moderate damage, CIPP can offer a seamless, jointless lining that conforms to the original pipe’s shape, even through bends and diameter changes.

- Spray-on Linings: For pipes suffering from corrosion or requiring a thin layer of protection, spray-on epoxy or polyurea linings can provide a durable barrier without significantly reducing the pipe’s internal diameter.

- Pull-in-Place (PIP) Linings: Suitable for larger pipes or those with access challenges, PIP linings allow for the precise positioning and curing of the liner.

- Segmented Linings: For large-diameter pipes or those with complex configurations, segmented linings can be custom-fabricated and installed in sections.

The customization of solutions extends beyond material selection, involving the adaptation of installation techniques to the site-specific conditions and constraints, ensuring the relining process is as effective and efficient as possible.

Conclusion

The success of pipe relining projects hinges on the thorough inspection and accurate diagnosis of pipeline conditions within plumbing systems. These initial steps ensure that trenchless pipe relining efforts are precisely tailored to address specific issues, utilizing advanced diagnostic technologies and materials to create effective, long-lasting solutions. Despite potential challenges, the strategic application of these processes enables efficient and minimally invasive repairs to the whole plumbing system infrastructure. Ultimately, the meticulous attention to inspection and diagnosis not only facilitates the immediate restoration of pipe functionality but also contributes to the longevity and reliability of underground piping and drainage systems. This approach underscores the value of trenchless pipe relining as a sustainable solution for maintaining the integrity and efficiency of modern plumbing systems.